Electromagnetic pan feeders regulate the flow of materials from storage to downstream equipment in industrial processes with exceptional feed rate control. This makes them an ideal solution for applications that require precise feed rates be set for downstream processes. In the recycling industry setting the correct feed rate for material entering a screen is crucial to ensuring high screen efficiency. Too much material and the screening efficiency will drop and off spec material will pass through the screen. Too little material and the throughput of the screen isn’t able to keep up with the production demands of the process, lowering overall productivity.

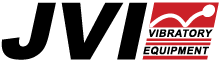

A customer recently reached out looking for a feeder to go under a hopper to feed scrap metal into a trommel screen. They required that the feeder extend into the trommel screen and to optimize the fit of the pan to the circular inlet of the screen. After speaking with the customer about the application and gaining a full understanding of their requirements, JVI was able to develop a custom electromagnetic pan feeder to meet their needs. The package that JVI designed included:

Electromagnetic Drive

An electromagnetic drive was chosen for the pan feeder for its precise, feed rate adjustability. Zero to 100% feed rate adjustability allows the feeder to operate at the lower rate necessary to optimize the screening efficiency of the trommel screen.

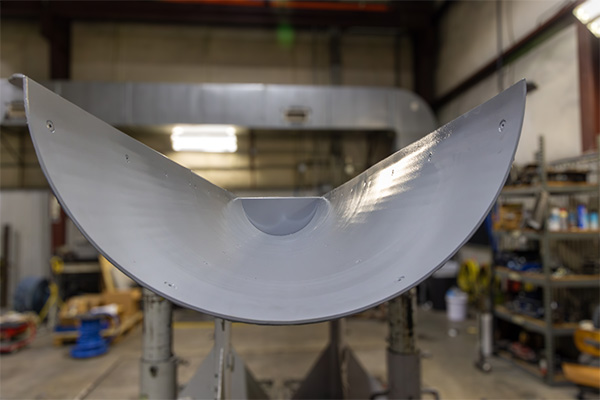

Semi-circular Pan

To meet the requirement of optimizing the fit of the feeder extending into the screen, JVI went with an extended semi-circular pan configuration. The semi-circular pan allowed the feeder to extend into the circular inlet of the screen with out allowing for excess open spacing. The pan extends father beyond the saddle than a typical feeder allowing it to reach inside the screen.

Replaceable Wear Liners

Bolt-in replaceable wear liners were added to the semi-circular pan to provide additional protection. Scrap metal is an abrasive material and adding the liners will help to extend the operating life of the feeder. Using replaceable liners that bolt in allows for easy removal and installation reducing maintenance downtime.

The package provides reliable, vibratory pan feeder that meets the requirements of application given by the customer. The feeder was approved and JVI began the manufacturing process. Today the vibratory pan feeder is integrated into the process providing reliable, low maintenance feeding of scrap metal from the hopper into the trommel screen at the desired feed rate.