Vibratory classifying screens separate closely sized particles for reliable product quality.

Delivering accurate material cut sizes for downstream processes.

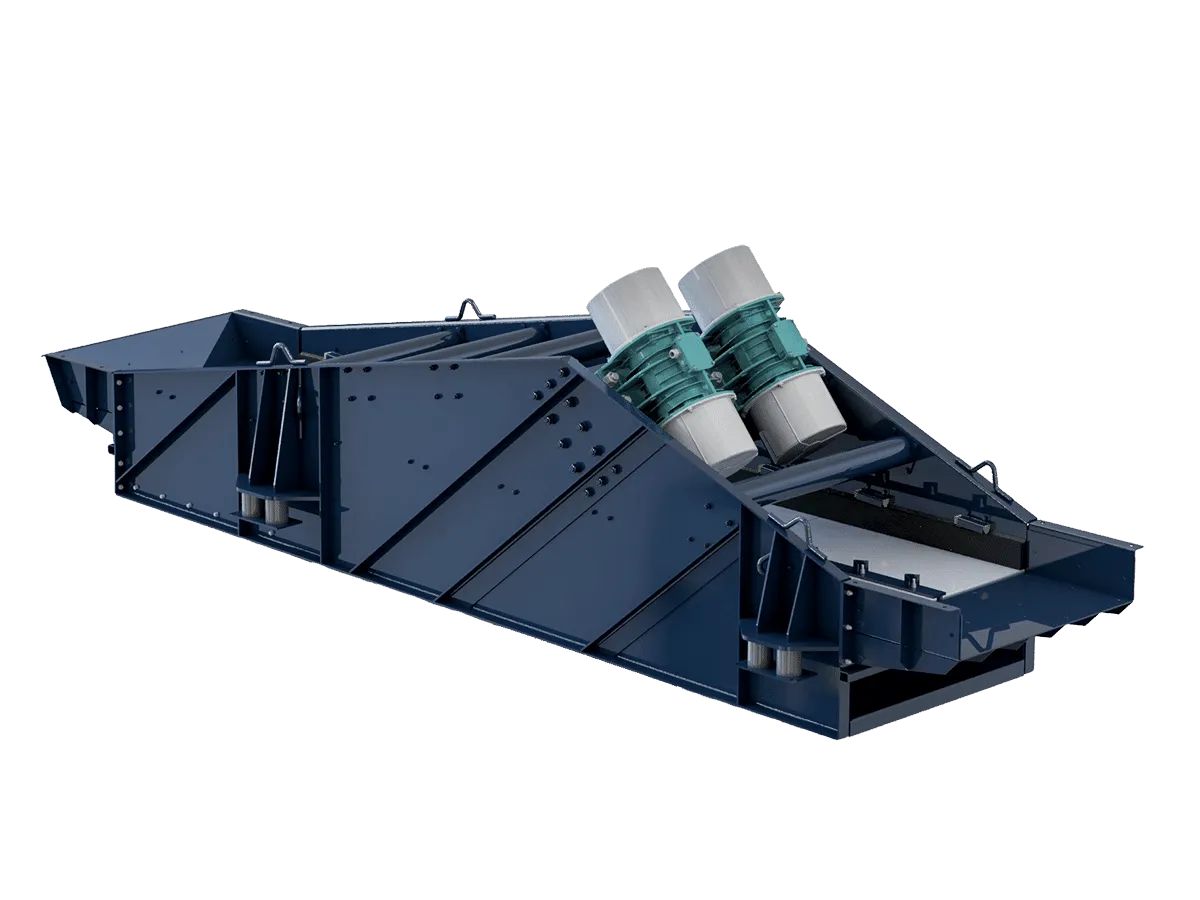

Vibratory classifying screens separate particles into desired cut sizes using principles of probability and stratification. These vibrating screens – also called linear classifying screens – are designed for applications that require specifically-sized material for handling by the next equipment in the industrial process.

They deliver accurate, consistent particle size separation and are capable of continuous operation and high throughput rates. Vibratory classifying screens are scalable to accommodate variable production volumes and can be manufactured in a wide variety of materials, screen deck arrangements, discharge configurations, and mounting arrangements. Drive options include electromechanical motors, electromagnetic drives, exciter drives, and dosing drives. They are designed to handle large volumes of bulk material.

Classifying screens particles into desired cut sizes for handling by the next equipment in the industrial process.

Quality manufacturing.

JVI vibratory classifying screens are used widely across many industries, including mining & aggregates, steel, recycling, plastics, chemicals, food & beverage and more.

We offer an extensive array of drive and motor types to handle light-duty applications, such as food and pharmaceuticals, up to heavy-duty applications, including mining, aggregates, steel, and recycling.

BACKED BY OVER

30 YEARS

OF EXCELLENCE

Founded in 1991, JVI Vibratory Equipment is field-proven for delivering low-maintenance, reliable equipment solutions for bulk material processing.

Our in-house team of engineers with extensive process knowledge, combined with stringent manufacturing and product testing procedures, delivers quality products that meet the exact requirements of each application. Let us know how we can help you:

Accurate, consistent particle separation. Tailored for each application.

Maximized Screening Efficiency

Each vibratory classifying screen is designed to maximize the probability that the correct particle size does pass through the screen deck, delivering optimal particle size separation.

Each screen is designed and manufactured to meet the requirements of the work envelope, the process, and the types of bulk material to be screened.

The JVI Material Testing Lab allows for testing of the bulk material properties in a customer’s application.

With this data, JVI engineers evaluate the screen-ability of the bulk material and optimize for screening efficiency.

Partnering with customers to design a customized screening solution.

Every application has unique challenges, including the type and amount of material, required cut sizes, environmental conditions. The JVI engineering team works with each customer to develop a classifying screen solution designed to their process and environmental requirements.

Multi-Deck Designs

JVI offers multiple deck designs that meet customer-specific process requirements, featuring one, two, or three decks. This allows material to be separated into two, three, or four distinct material flow streams based on particle size and requirements.

JVI offers a wide variety of customization options including side discharge, covers, inspection ports, and materials of construction.

Wide Variety of Deck Construction

- Woven wire decks are used in many applications featuring larger open areas.

- Wedge wire decks are typically used for dewatering applications.

- Perforated decks are used for longer wear life when screening abrasive materials.

- Rubber decks are often used for highly-abrasive and/or high-temperature material.

- Polyurethane decks can extend the wear life by 4x to 5x when used with abrasive material.

Food Grade and Washdown Ready

JVI classifying screens are suitable for food grade and pharmaceutical applications with stainless steel construction finished to the specified mechanical or electro-polish requirements.

Hazardous Location Certified

Where dust ignition is a concern, JVI classifying screens are available with explosion-proof motors designated by CSA & ATEX certifications. All JVI vibratory screens are available with Class II, Division I certifications and ATEX equivalent.

Robust Construction for Tough Environments

For harsh environments, JVI Classifying Screens are designed with more robust, thicker construction materials, and abrasion resistance liners on wear areas.