Vibratory dewatering screens reduce moisture in slurries and bulk materials.

Improve storage efficiency, water containment and conservation, cleaner handling of material, reduce costs and improve product consistency.

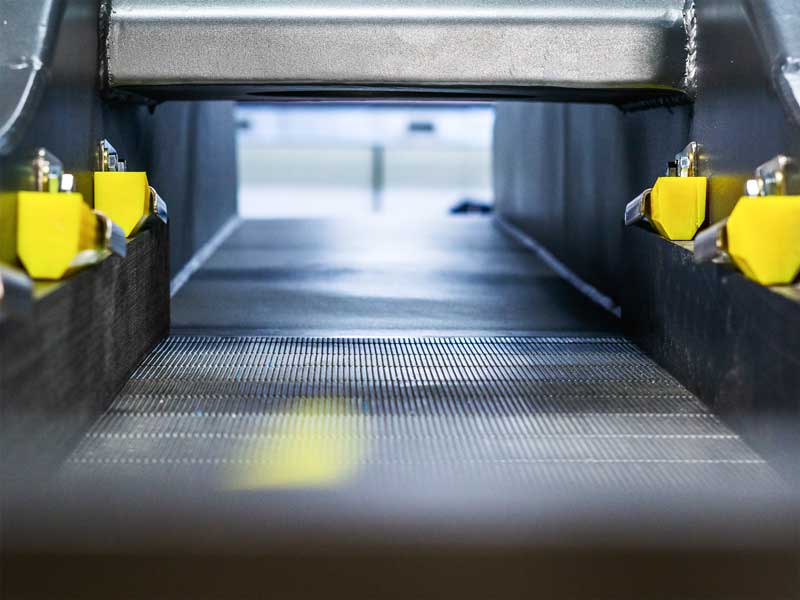

Dewatering screens reduce the percentage of free moisture from bulk materials prior to downstream processing. Vibratory dewatering screens use vibration to remove moisture from solid material as it is transported over the screen deck.

Removing excess water from solid bulk material enables faster drying and reduces weight and volume of the final product for cost savings in transportation, storage, and downstream processing.

Dewatering screens remove excess water from solid bulk material prior to downstream processing.

Heavy-duty construction.

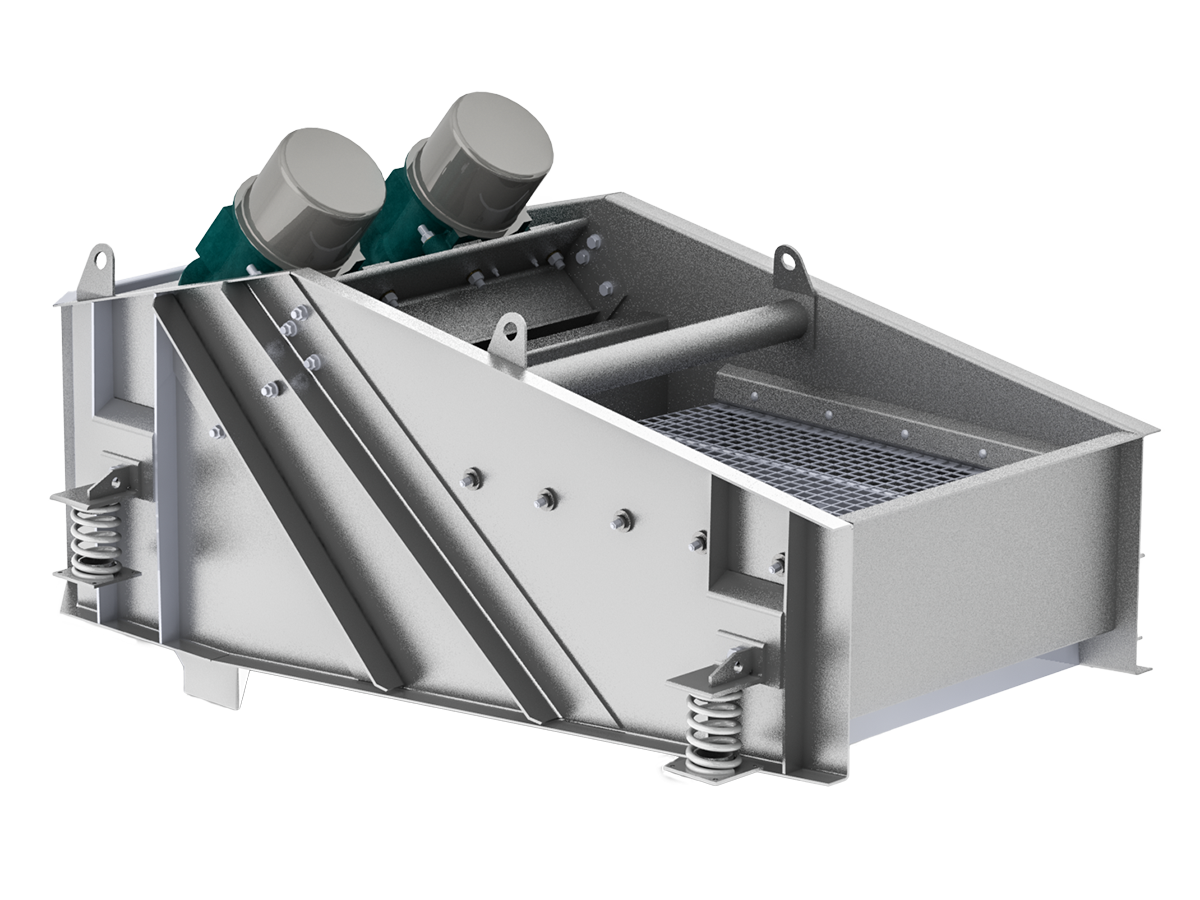

JVI vibratory dewatering screens are heavy-duty electromechanical screening equipment designed to handle several types of materials, including sand, minerals, crushed aggregates and other granular materials, as well as other slurry applications.

JVI dewatering screens are custom built of rugged and durable materials. JVI vibratory dewatering screens are used in a variety of industries, including mining & aggregates, steel, recycling, and more.

BACKED BY OVER

30 YEARS

OF EXCELLENCE

Founded in 1991, JVI Vibratory Equipment is field-proven for delivering low-maintenance, reliable equipment solutions for bulk material processing.

Our in-house team of engineers with extensive process knowledge, combined with stringent manufacturing and product testing procedures, delivers quality products that meet the exact requirements of each application. Let us know how we can help you:

Reduce moisture to as little as 15%

Higher capacity storage

Additional storage capacity is gained by the removal of water from the bulk material. The reduction in water content also improves the angle of repose allowing for higher stack heights. Less moisture in the bulk material reduces the decanting period required before sell can.

Improve drying and product quality

Dewatering screens are commonly used to prepare bulk material for the drying process. Lowering the moisture content of material prior to drying reduces the energy necessary to achieve the required final moisture content. It also provides a more uniform material prior to drying, which helps produce a more consistent and higher quality end product.

Reduce environmental impact, Recycle Water

Recovered fluid from a dewatering screen can be controlled for easy recovery and reuse. Reducing the need for water treatment and disposal lowers environmental impact and helps with regulatory compliance.

Improve facilities housekeeping

Dryer material exiting the dewatering screen is easier to handle for downstream equipment promoting a cleaner working environment. Equipment maintenance is reduced. Less labor for cleanup efforts is required.

The JVI Material Testing Lab allows for testing of the bulk material properties in a customer’s application.

With this data, JVI engineers evaluate the screen-ability of the bulk material and optimize for screening efficiency.

Simple, single mass design. High quality manufacturing.

Built for continuous operation. Longer product life.

Single mass technology is a simple design approach that minimizes moving parts and ensures longer product life. JVI dewatering screens are built to handle abrasive products for continuous operation in harsh conditions.

Electromechanically Driven

Single mass construction means that screen vibration is driven by two electromechanical unbalanced motors mounted directly to the screen body.

Explosion-Proof Certification

JVI vibrating screens can be supplied with CSA certification for Class II, Division I, Groups E, F & G dust explosion areas or ATEX certified unbalanced motors.

Single mass design simplifies construction for a more durable, longer life.