A refinery coproducts producer was beginning to experience increasing maintenance issues and downtime due to an aging integral shaft classifying screen. The screen had reached the end of its expected operational life, and the refinery was in need of a replacement screen that could be easily incorporated into the existing pet coke screening process. The replacement screen needed to separate petroleum (pet) coke at +6” material size at temperatures up to 300°F and achieve a rate of 400 tons per hour (TPH). The producer turned to JVI Vibratory Equipment to design and manufacture a custom replacement grizzly screen engineered to fit into their petroleum coke processing operation.

The Challenge: Replacing an Aging Classifying Screen

Ever increasing downtime and maintenance costs of the existing screen were driving up costs and production delays. To meet their desired production output the producer needed a replacement capable of delivering consistent 400 TPH throughput while reliably separating +6” pet coke. The overs would be routed to a crusher, while the unders would bypass the crusher. The replacement screen needed to withstand pet coke’s high abrasion and temperatures (up to 300°F), while providing high operational reliability and low maintenance. After reviewing the requirements, JVI designed a custom grizzly screen engineered to operate within the existing petroleum coke processing process.

JVI’s Custom Engineered Solution

Grizzly Screen vs Classifying

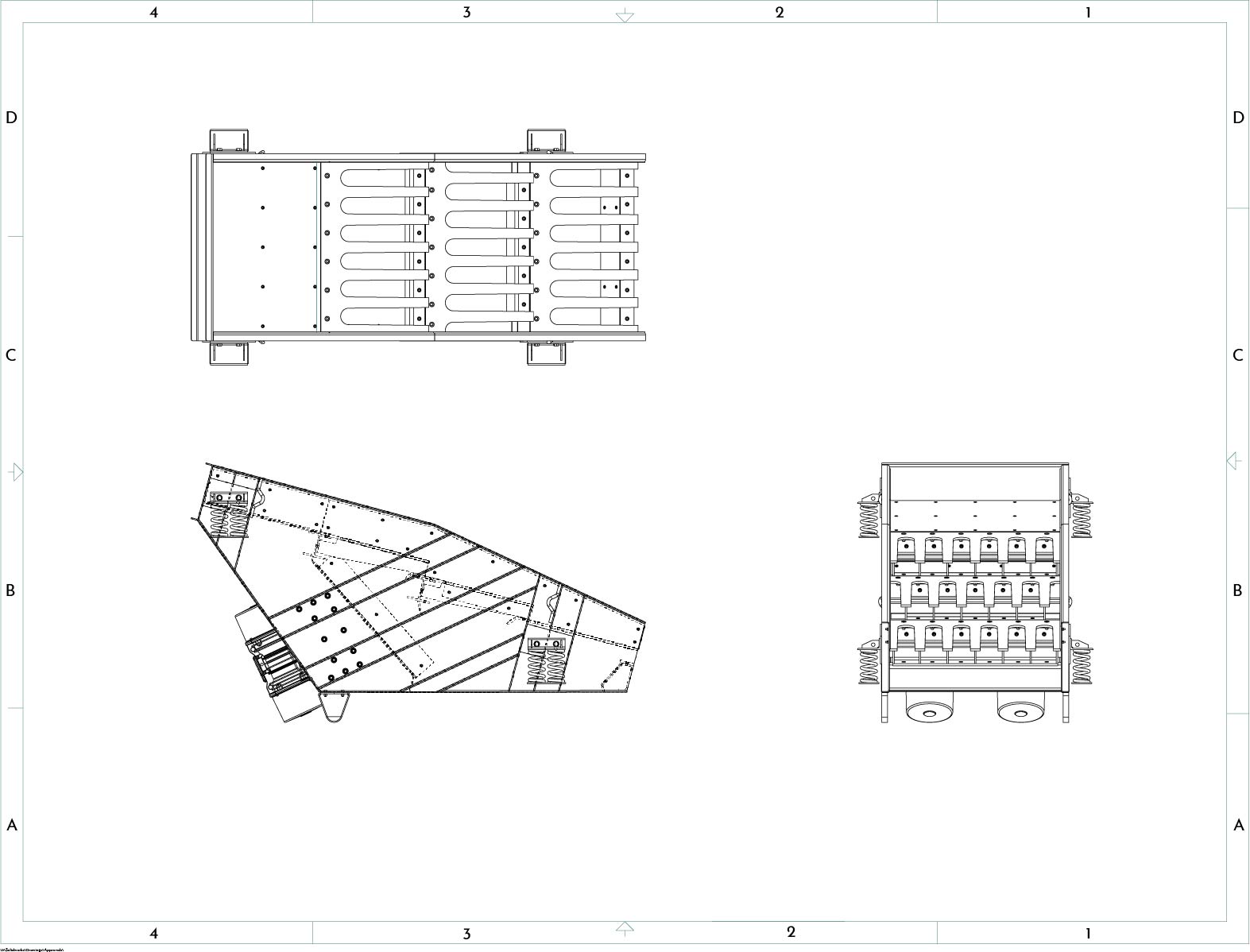

In working with the customer, it was determined to replace the classifying screen with a grizzly screen. This decision was made based on the application of separating +6” pet coke prior to entering a crusher. When screening material prior to entering a crusher a high level of accuracy is not required. The coarse separation that a grizzly screen provides the required material separation for feeding a crusher, while also improving operation efficiency and up time. The grizzly fingers help to prevent material from plugging which ensures that screen efficiency is maintained and reduces downtime for maintenance of plugged material in the deck.

No External Moving Parts

JVI utilized a dual electromechanical motor design, which features fewer operating components compared to the integral shaft design. This approach delivers higher reliability and lower maintenance requirements. This is achieved through the reduced wear parts and no exposed moving parts like those found on integral shaft designs. For petroleum coke processing, the dual electromechanical motors ensures predictable, dependable performance without operational complications.

Grizzly Finger Screen Deck

The grizzly fingers represent the critical component responsible for separating the on-spec materials out and sending the overs to a downstream crusher. The deck consisted of three 39-inch stepped grid sections of custom manufactured grizzly fingers. The fingers utilize 3/4-inch thick 316 stainless steel plate wear liners on all material-contact surfaces. The fingers feature a diverging design that gradually increases the opening between the fingers. This feature helps to prevent material sticking between the fingers.

Full Wear Liner Coverage

Recognizing petroleum coke’s highly abrasive material characteristics, JVI incorporated full wear liner coverage on all material contact areas. ½” thick 316 stainless steel liners cover the impact are where material first contacts the screen, while the side walls and discharge areas are protected with 3/8” thick 316 stainless steel liners. All the liners are bolted and fully replaceable, allowing the refinery to replace the worn liners as needed.

Performance Specifications

• Capacity: 400 TPH

• Material: Raw petroleum coke (50-55 PCF, -24″ particle size)

• Temperature: Up to 300°F

• Screen: +6” material

Site Visit and Start Up Supervision

JVI’s commitment to customer success extends beyond equipment delivery. The proposal includes comprehensive onsite startup assistance featuring:

Technical Expertise

A JVI technician provides onsite startup supervision to ensure complete satisfaction and optimal performance from day one.

Personnel Training

Comprehensive training for the customer’s operating personnel ensures proper operation and understanding of the equipment’s capabilities.

Maintenance Planning

JVI provides detailed preventative maintenance requirements and schedules, helping the refinery maximize equipment life and minimize unplanned downtime.

Project Approval and Results

After reviewing JVI’s comprehensive proposal, the customer approved the custom grizzly screen package. Upon successful installation and commissioning, the JVI grizzly screen has delivered significant improvements to the producer’s operations.

Project Execution and Results

The replacement grizzly screen successfully restored optimal performance to the producer’s petroleum coke processing workflow. Unlike the aging screen it replaced, the new equipment delivers consistent 400 TPH throughput, reliable material separation, and dependable performance without the recurring failures that had disrupted operations.

For industrial facilities facing similar challenges with aging petroleum coke processing equipment or other high-temperature, high-abrasion applications, JVI’s custom vibratory equipment solutions offer a proven path to improved efficiency, extended equipment lifespan, and simplified operations. The success of this replacement installation demonstrates JVI’s commitment to providing engineered systems that replace aging equipment while delivering both immediate operational improvements and long-term value.