Vibratory cone crusher feeders are time-tested performers in aggregates and mining.

Extend the service life of your cone crushers and increase production output, too.

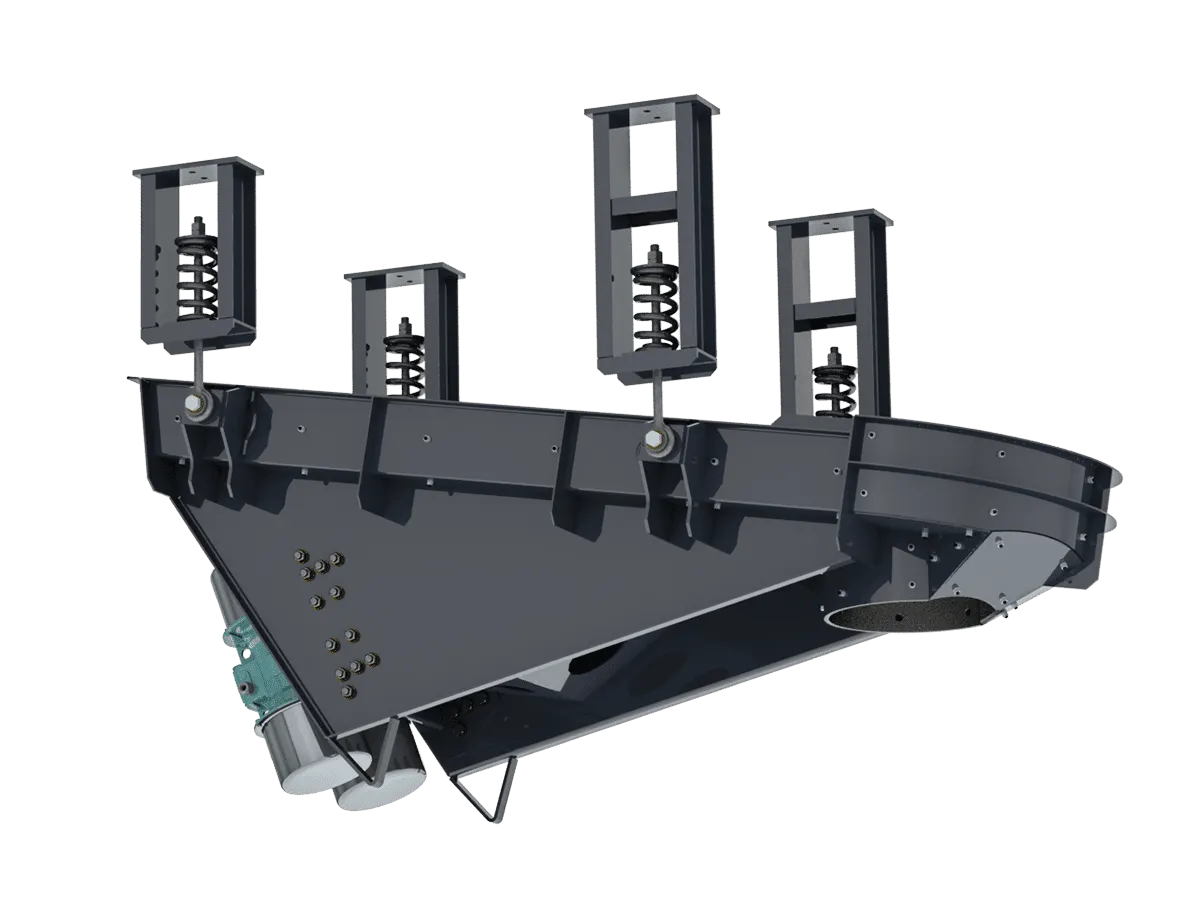

JVI vibratory cone crusher feeders are heavy-duty, time-tested performers in the aggregates and mining industry. Cone crusher feeders deliver a uniform 360-degree peripheral feed of material into tertiary or quaternary cone crushers.

This even material distribution allows for higher yields of cubic shaped product and prolongs the cone crusher’s service life.

Every JVI vibratory cone crusher feeder is designed specifically for your application and work envelope requirements.

JVI cone crusher feeders deliver a uniform 360-degree peripheral feed of material into tertiary or quaternary cone crushers.

Heavy-duty industrial feeders.

JVI electromechanical feeders are used widely in aggregates and mining, across North America and around the world. JVI electromechanical single mass feeders are ideally designed for the harsh environments and abrasive material handling. The hallmark of JVI electromechanical feeders is the simple design of single mass technology.

Vibratory drives and the feeder body are connected as one. This delivers a solution that eliminates extraneous springs, pulleys and other associated maintenance parts that are required in two-mass feeders. Natural frequency tuning is eliminated.

BACKED BY OVER

30 YEARS

OF EXCELLENCE

Founded in 1991, JVI Vibratory Equipment is field-proven for delivering low-maintenance, reliable equipment solutions for bulk material processing.

Our in-house team of engineers with extensive process knowledge, combined with stringent manufacturing and product testing procedures, delivers quality products that meet the exact requirements of each application. Let us know how we can help you:

World-class electromechanical drives.

JVI vibratory cone crusher feeders are driven by our Aviteq brand electromechanical unbalanced motors. These high torque, high force output motors are designed specifically for driving the JVI heavy duty vibratory equipment. Each one is CSA certified for Class II, Division I, Groups E,F,G areas.

Our electromechanical unbalanced motors are:

- Available in over 94 different models including 3600, 1800, 1200 and 900 RPM versions

- Rated for continuous duty at 100% force output and suitable for wash-down

- Explosion-proof with CSA & ATEX certifications available

- JVI maintains a complete stock of these motors in our Houston, Texas facility

Simple VFD control packages deliver precise feed rates.

When operated with a standard variable frequency drive (VFD), the feed rate from a JVI electromechanical cone crusher feeder can be continually adjusted in real time to meet the changing dynamics of the industrial process.

This allows for the production process to be automated with sensors down the production line that communicate with the VFD and adjust the feed rate as necessary. Maintaining the optimal volume of bulk material flowing into downstream crushers keeps the production process running smoothly.

The JVI Material Testing Lab provides testing of the bulk material properties in a simulated application.

With this data, JVI engineers confirm the feeding and conveying characteristics of the bulk material and optimize design.

Custom designed for use with various types of cone crushers.

JVI vibratory feeders are custom designed and built to work with primary and secondary crushers (standard pan feeder end discharge) and all types of tertiary and quaternary cone crushers, such horizontal shaft impactors (HSI), vertical shaft impactors (VSI), single cylinder or multi-cylinder crushers, hammer crushers, jaw crushers, or hydraulic crushers rated for all capacities.

Available Integrated trolley system for easier maintenance.

JVI Cone Crusher Feeders can include an integrated trolley system package. The trolley system allows for the feeder to be indexed above the cone crusher during operation and indexed out from over the crusher during maintenance. This allows for easier access to both the cone crusher and cone crusher feeder for routine maintenance and service.

Eliminates the need for a rotating feed distributor.

For tertiary or quaternary crushers, direct 360-degree peripheral feed into the cone crusher eliminates the need for rotating or other type feed distributors. The vibrating action of the center hole feeder delivers an all-in-one design that simplifies installation, while optimizing the process and results.

Minimizes uneven rock wear and build up in the crusher.

The uniform peripheral feed into the cone allows for even wear on the cone liners. This extends the overall wear life of the crusher and reduces maintenance downtime that can halt production.