Mechanically-driven, heavy-duty work horses keep bulk material moving.

Single mass technology keeps it simple for efficiency and longer run life.

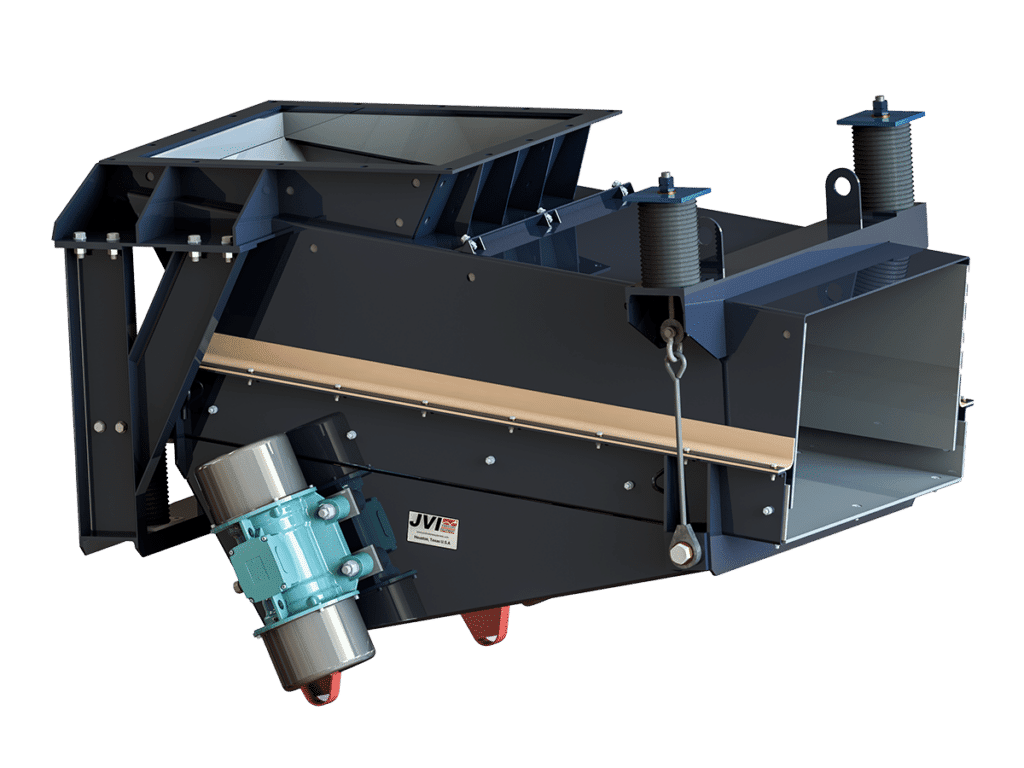

JVI electromechanical pan feeders are time-tested for heavy-duty work across a wide variety of industries to feed bulk material consistently at specified feed rates. They are the preferred vibratory feeder in high-volume applications, such as railcar hoppers, truck dumping stations, and surge tunnel feeders.

They are ideal for discharging hoppers and spreading material across widths up to 10 feet downstream into crushers, mixers, screens or dryers, where spreading material evenly and regulating flow improves process control and equipment life.

Every JVI electromechanical pan feeder is designed specifically for each customer’s application and work envelope requirements. Electromechanical motors are one drive option for Vibratory Pan Feeders. View also Electromagnetic motors.

The JVI electromechanical pan feeder is a time-tested work horse for feeding dry bulk material consistently at specified rates.

Hard at work in many industries.

Introduced in 1991, JVI electromechanical pan feeders are used widely across many industries, including mining and aggregates, steel, recycling, plastics, chemicals, food & beverage and more.

For over 30 years, JVI has delivered electromechanical pan feeders – also known as brute force feeders or shaker feeders – to customers across North America and around the world.

BACKED BY OVER

30 YEARS

OF EXCELLENCE

Founded in 1991, JVI Vibratory Equipment is field-proven for delivering low-maintenance, reliable equipment solutions for bulk material processing.

Our in-house team of engineers with extensive process knowledge, combined with stringent manufacturing and product testing procedures, delivers quality products that meet the exact requirements of each application. Let us know how we can help you:

Advanced vibratory technology. Simple design.

JVI introduced its electromechanical pan feeder to the North American market in 1991 with advanced, best-in-class applied vibratory technology. The electromechanical is a single mass machine with integral drive systems design and selected to fit each customer’s applications. The design is simple eliminating extraneous components and the requirement for tuning.

JVI electrotechnical pan feeders can be configured to handle almost any type of material that needs to feed.

Custom engineered for your mid-to-heavy-duty application.

Every bulk material handling process comes with its own unique challenges. Type and amount of material being fed and the environmental conditions of the operating location vary by industry and company. The JVI engineering team works closely with our customers to develop a custom solution designed to handle their exact material and environmental conditions.

Explosion proof to food grade.

JVI pan feeders can be designed to work in very diverse applications, from stainless steel pans required for food grade material to explosion proof motors for hazardous areas. We partner with customers to engineer application-specific equipment using proven design standards.

Improved design. Retrofit to your existing process.

The JVI engineering team excels at retrofitting a new vibratory feeder into your current process. This means you get the benefits of a new, higher-performing feeder without the time and cost of redesigning your existing process.

The JVI Material Testing Lab provides testing of the bulk material properties in a simulated application.

With this data, JVI engineers confirm the feeding and conveying characteristics of the bulk material and optimize design.

Electromechanical Pan Feeder in Action

This video shows the JVI single mass technology with two unbalanced motors mounted directly to the saddle, connected to the hopper by our unique Chute Work Package. The need for exciter springs and natural frequency tuning is eliminated. Bulk material discharges from the hopper evenly at a controlled feed rate.

A word about single mass technology:

JVI electromechanical pan feeders utilize single mass technology in which the feeder is driven by two electromechanical unbalanced motors — or optional exciter drives — mounted directly to the feeder body, also known as the saddle. This single mass technology eliminates the need for exciter springs or natural frequency tuning.

Simple Design

By engineering a simple design with fewer moving parts, JVI manufactures pan feeders that keep working, even in the harshest industrial environments. Eliminating exciter springs, v-belt drives, and sheaves that are needed to run two mass vibratory feeders offers ease of maintenance and longer run life.

Single mass technology eliminates the need for exciter springs or natural frequency tuning.

Two unbalanced motors work together.

Enhanced feed rate adjustability.

Hard at work in the recycling industry.

No Tuning Required

JVI single mass electromechanical pan feeders do not need tuning to generate the vibration required for peak to peak movement that is common in the two mass feeders found in the North American market.

This single mass design is both simple and rugged for long and reliable service life. Mechanical failures and tuning issues caused by sticking material, high headloads, low headloads, or no material present are reduced or eliminated.

Enhanced Feed Rate Adjustability

When operated with a standard variable frequency drive (VFD), the feed rate can be adjusted continually in real time to meet the changing dynamics of the industrial process. This allows automating the production process with sensors along the production line that communicate with the VFD and adjust the feed rate as necessary.

Dry bulk material moves downstream into crushers, screens, and other processing equipment at the optimal rate, keeping the production process running smoothly.

Rated for the Demands of Your Application

Electromechanical unbalanced motors and exciter drives are designed to work with our vibratory equipment and selected for each application. These drives are:

- Available in over 94 different models including 3600, 1800, 1200 and 900 RPM versions

- Rated for continuous duty at 100% force output and suitable for wash-down

- Explosion-proof with CSA & ATEX certifications available